An industry leader in design, fabrication, and construction. We are renowned for our quality, cost effectiveness, innovative approach, and professional discipline.

(07) 3908 9600

Email: [email protected]

idec Solutions Pty. Ltd.

265 Queensport Rd N, Murarrie QLD 4172

What We Do

Industry Leader in Design, Fabrication & Construction

What We Do

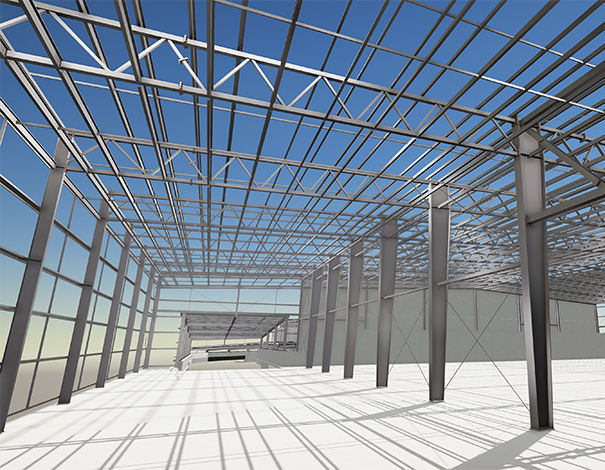

idec Solutions is a licenced builder whose in-house capabilities include Design & Engineering, Detailing, Fabrication, Construction, Rigging, Remote Infrastructure and Acoustic Solutions. idec offers a full turnkey solution from concept through to practical completion and is more than qualified to undertake your next project.

Specialising in the design and construction of commercial and industrial buildings and custom-engineered structures, idec Solutions has the capability, experience and capacity to undertake any project. Additional to our turnkey solutions, idec offers workshop drawing, fabrication and steel/precast erection services to other builders to ensure exceptional project outcomes.

Design & Engineering

Design & Engineering

All our design work is carried out in Australia and is fully compliant with all relevant Australian Standards.

Our qualified personnel can help develop your ideas and needs by preparing design documents such as:

- Structural engineering documentation for all types of structural steelwork.

- Supporting concrete (foundations, slab, tilt panels, etc).

- Structural engineering design and certification for building construction and approval.

- Built up plate (BUP) non-prismatic portal frames for wide clear spans.

Structural & Civil Engineering

Our engineering and drafting team has the capability to provide structural and civil engineering services in the following areas:

- Materials handling industry

- Cranes, hoists, lifting structures

- Communication towers

- Structural audit and reporting

- Mobile energy generation and communication modules

Detailing

Detailing

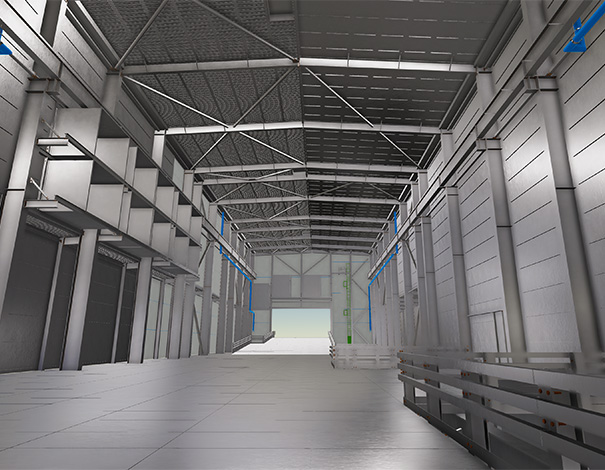

With in-house Steel Detailers in Brisbane, idec has the ability to produce workshop drawings for any size job. The quality of the drawings produced by our professional detailers ensures that the fabrication of steel in our workshop proceeds without issue. idec utilises best-in-class software in our design and drafting process, including:

- TEDDS

- AutoCAD

- Tekla Structures

- Revit

Customised reports, assembly drawings, single part drawings and 3D erection drawings are all linked to the 3D model to ensure all documentation is integrated and accurate to assist with fabrication and erection. For complex projects, we also utilise 3D scanning and can incorporate the results in our 3D models.

idetail3D

idetail3D provides a one-stop-shop for detailing and modelling. Idetail3D’s team of expert detailers can provide the following to suit all individual workshop requirements and steel suppliers:

- Workshop Drawings

- Site Erection drawings

- DXF & CNC Data

- Fittings Drawings

- BIM Modelling

Trimble Connect is utilised for communication between both idec and idetail3D and clients to ensure efficient collaboration and real-time updates.

For more information about idetail3D visit www.idetail3d.com.au

Processing

Robotic Steel Processing

idec is home to Queensland's fastest steel processing line which supports our fabrication capabilities through world-leading Voortman robotic technology. We can cut, drill, cope and scribe all raw steel in-house, leading to increased efficiency.

Our processing line is closely linked to the Digital Engineering Team - meaning that model information can be directly imported from Tekla to the Voortman. This results in the consistent, reliable and accurate transfer of information between the shop drawing and fabrication process.

The Voortman technology includes:

- V631 Robotic Drilling Machine

- VB1050 Automated Sawing Machine

- V807 Robotic Coping System

- Intellegent in-feed out-feed System

Fabrication

Steel Fabrication

Our modern, purpose-built workshop facilities are fitted with overhead cranes, automated beamline and tractor welding machines – all of which are operated by experienced and qualified tradespersons, ensuring that the finished product is fabricated and manufactured accurately and on time.

We have the capacity for up to 2000 workshop hours per week and over 3,000t per year. Our 3000m² workshop contains the following equipment:

- 20t overhead cranes

- Beamline welding machine

- Oxy cutting equipment; Plasma Cutter

- 115t punch and shear machine

- Industry-leading Voortman robotic machinery

- 7t forklifts

Compliance

idec is one of a just a few CC3 certified fabricators in Queensland and as such all idec fabrication complies with:

- AS4100 – Steel Structures

- AS1554 – Welding of Steel Structures

- AS5131 – Structural Steelwork – Fabrication and Erection

Specialised Fabrication

For high-end fabrication needs, idec is the perfect choice. We are experts in the fabrication of specialised items such as:

- Pipe racks, crossovers and platforms

- Chutes

- Skids

- Crane beams

- Intricate stair frames

- Communications and electrical generation module frames

- Any structure that requires welding to AS/NZS 1554.1:2014

We have highly qualified fabricators and welders together with a fulltime team of QA personnel.

Construction

Comprehensive Construction

idec offers a comprehensive construction service to the industrial, resources, commercial, communications, recreational and educational industry sectors. To facilitate construction, idec utilise in-house capabilities including professional engineering, fabrication and rigging.

Design & Construct

idec specialises in providing a full turnkey service. idec not only design and construct your building, but also manage the pre-construction phase including geological surveys, architectural design, council approvals and building certifications.

idec minimise constructability issues by becoming involved early in the project. This enables idec to manage a project’s cost, quality and duration more effectively and efficiently. The primary benefit to the client is only dealing with a single entity. This not only creates financial savings but removes stress, allowing you to focus on your business.

Rigging

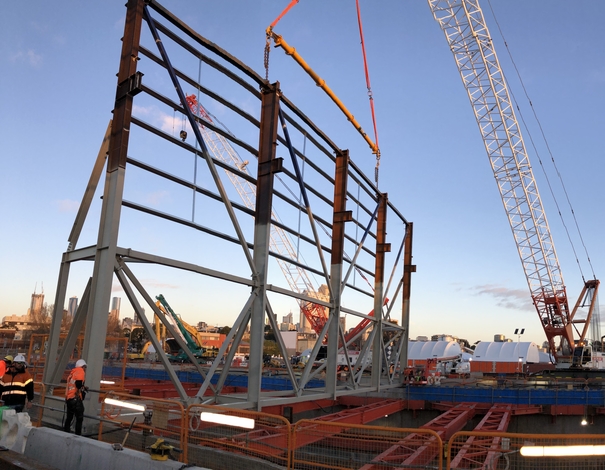

Integrated Rigging Solution

As part of idec’s integrated construction solution, idec typically relies on its own riggers for the delivery of its projects. Having in-house rigging capability enables idec to maintain control over the safety, quality and time of a project throughout the construction process.

Experienced Riggers

The idec rigging team has a number of crews made up of a number of highly skilled and experienced Riggers that are mobile and capable of erecting structures anywhere in Australia. Furthermore, the rigging team has the capability to dismantle temporary structures such as acoustic buildings and mining camp buildings across the country.

Remote Infrastructure

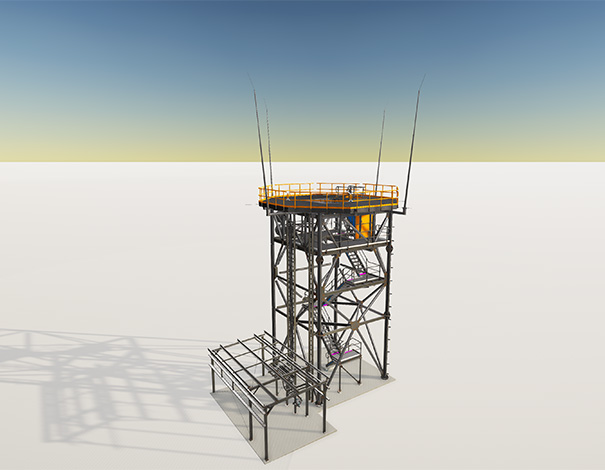

Expert Remote Builder

idec has completed many remote projects across Australia. With our in-house specialties in design and construct, we possess the skills, experience, expertise, as well as excellent quality and safety systems to undertake your project. idec is driven to perform in the remote infrastructure field and this is evident from our past experience of diversifying into the tower and communications divisions – undertaking specialised projects throughout Australia and the Asia Pacific.

Civil Works & Site Services

Effective civil works are fundamental to the stability, safety and longevity of remote infrastructure. Idec specialise in the design and construction of civil works at remote sites and understand the challenges associated with working at remote and difficult sites.

As part of the establishment or redevelopment of a remote infrastructure site, idec, through its key project partners, can provide site services for your project.

Vertical Infrastructure & Equipment Installation

Idec provides turnkey vertical infrastructure solutions. With our multi-faceted, in-house capabilities, we are able to deliver quality solutions for your vertical infrastructure. idec provides technical rigging for all your equipment installation and commissioning requirements.

Acoustic Solutions

Acoustic Sheds

idec provides acoustic building solutions that enable 24-hour operations on major projects, minimising noise risk and assisting contractors in maintaining a positive public profile during construction.

idec has developed a number of acoustic solutions that have been laboratory tested by independent NATA accredited acoustic consultants.

Specialised Design

Public opinion of a construction site remains paramount and idec has become proficient at reigning in the noise of all types of structures; idec believes that this specialisation provides a particularly great advantage for construction in urban areas. idec can design acoustic solutions that minimise both the visual and environmental impact on surrounding areas.